Reverse Engineering

Most Trusted Reverse Engineering Service Company in India

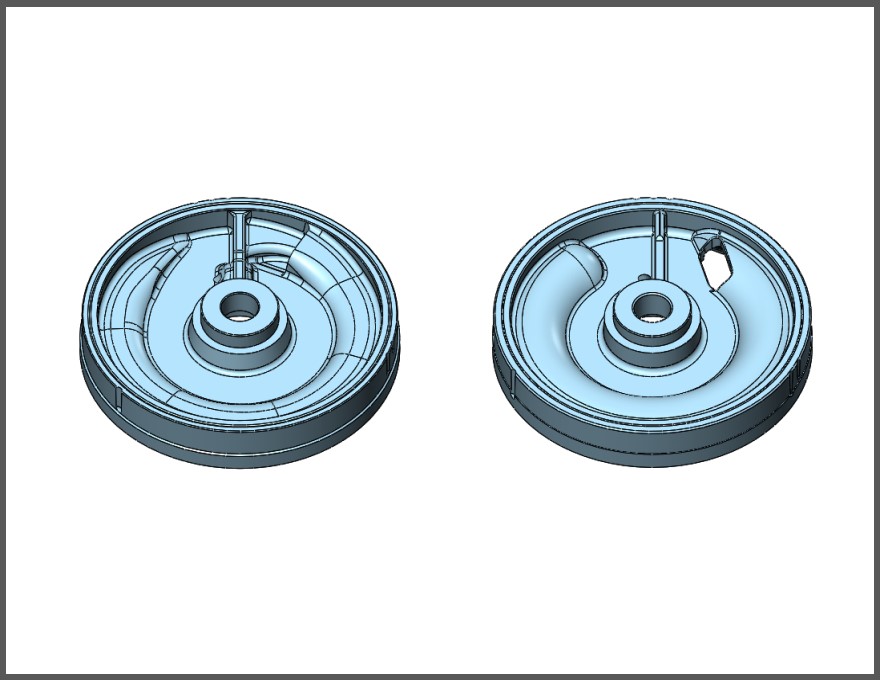

The Reverse Engineering Services is a process of converting 3D scanned data into a parametrically precise 3D CAD model. Design and Automation Services India offers Reverse Engineering Services to assist your physical needs. By using our 3D laser scanning technologies and 3D CAD software, we are able to assist you in capturing the measurements and enter them into 3D Product Development software.

Our 3D reverse engineering services in India is combination of all the necessary tools like engineers with best industry experience and expertise to complete the most difficult reverse engineering project in India with 100% client satisfaction. Each and every service you need is getting done in-house so no need to go somewhere else for your different requirements. Our engineers are experienced and skilled in 3D scanning services and all the technologies we have to make your work easy. we also provide 3D modelling, product design, product development, and product design rendering services.

We have experienced team in Ahmedabad, India to handle number of Reverse Engineering projects at the same time and we also have worked with wide range of industries to complete their Reverse Engineering requirements. We are always looking forward to work with you as well.

3D Scanning & Reverse Engineering

If the opportunity to use Reverse Engineering Services presents itself, Design and Automation Services has more than 10 years of experience in providing such services to engineers, designers, and product manufacturers in India and other countries like USA, Canada, Australia, UK, Bulgari, and many more. Following ISO quality standards, we have the resources and capabilities to offer 3D Scanning services to our clients. We follow a carefully managed below process for 3D Scanning which includes:

- The client provides the physical components, Parts, or share detail picture for our teams to examination.

- We perform a laser scan of the component and extract cloud point data to our systems.

- Using this data, our team generates a 2D or 3D CAD model for use in product enhancement. This may include failure analysis, reproduction, general study, inspection, or application for a new product or design.

3D Scanning and Reverse Engineering both are not the same, they both are two different technologies but they are so much perfect when work together. In the process first 3D scanning of a model or component take place then you get a perfect process point to start Reverse Engineering process.

3D Printing & Reverse Engineering

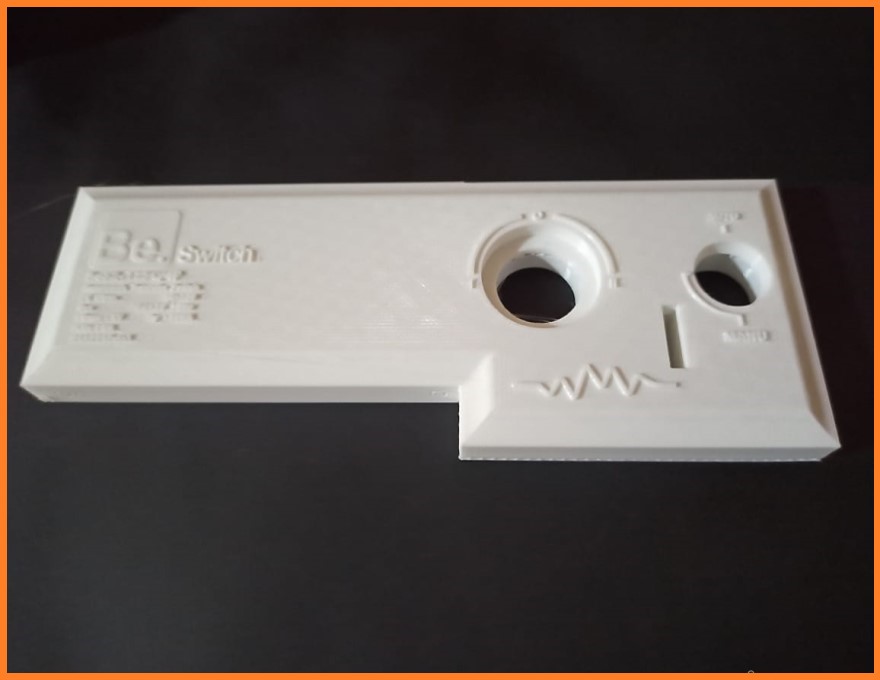

3D Printing is a process for making a physical object from a three-dimensional CAD model, typically by laying down many continuous thin layers of a material. It fetches a digital object (its CAD representation) into its physical form by adding layer by layer of materials. Each of these layers can be seen as a thinly sliced horizontal cross-section of the final object. 3D printing is the reverse of subtractive manufacturing which is cutting out / hollowing out a piece of metal or plastic with for instance a CNC machine.

Reverse Engineering Services

-

3D Scanning

-

Rapid Prototyping

-

Point clouds to 3D CAD

-

CMM inspection

-

Manual measurement of processing plant

If you are a manufacturer or a plant owner using equipment further than their design life; reverse engineering is the solution for you to remanufacturer and replace these parts with the exact original design and functioning.

Enabling engineering clients to restore obsolete design data, our reverse engineering services provide digital design information for the products to remain competitive in the market. Our close collaboration with client’s design team provides opportunities to explore alternative concepts or revamp existing ones, fuelling innovation during product development process.

Advantages of Our Reverse Engineering Services

There are too many advantages of Reverse Engineering. A design process should always start with Reverse Engineering to get the optimum end results. With reverse engineering, you can do analysis of your design and revise your product as well. and these data work very well in manufacturing process. 2D and 3D drawings can be created with the information. 70% cost of design and prototyping process can be reduced with help of Reverse Engineering Services.

If you are in need of Reverse Engineering in India, USA, Canada, Australia, UK, Bulgari or any other country then get in touch with us today.